Innovative Design, maximum Flexibility: The New Generation of Flectra Flectra Labeling Machine / KOSME

With the new Flectra labeling machine, KOSME, a Krones Group company, is opening a new chapter in labeling technology. In addition to a precise and powerful labeling solution, KOSME is focusing on a revamped user experience for the first time. Based on HELIO, a new UI and UX concept was created – developed from on-site analyses and a consistently user-centered approach – that sensibly combines the experience of KOSME and Gernep: compact, flexible, and easy to use.

Implementation

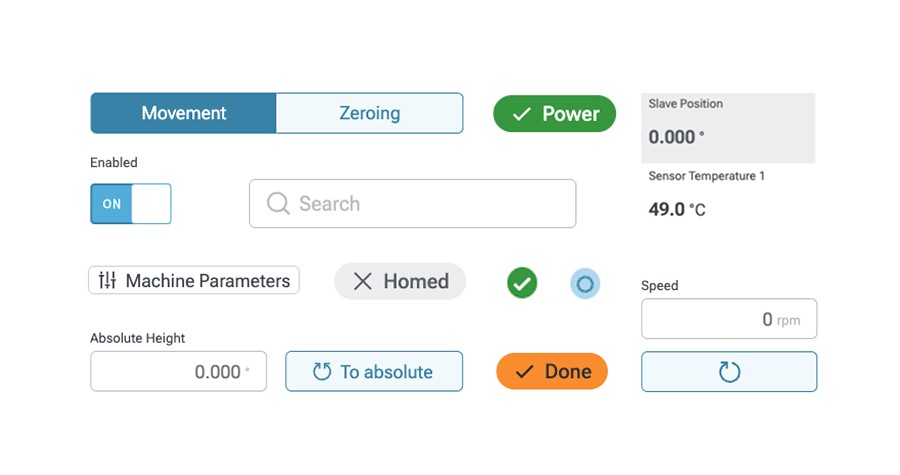

Based on the powerful SDK, several specialized custom extensions were also created, which are now available to all project planners. They integrate seamlessly into the existing control library and enable flexible implementation of the various expansion stages of the Flectra series. The operating concept is complemented by a light and dark theme based on the Krones Group's design system, which supports a consistent, ergonomic user experience. The new HMI generation combines a clearly structured design with efficient usability and facilitates safe, rapid operation of the machine – even for more demanding processes.

Challenge and Usage

Bottle labeling is carried out at high cycle speeds, presenting operators with challenging tasks. Operators must load the dispenser modules with new label rolls in good time to ensure uninterrupted operation. At the same time, they keep an eye on the ejection process to identify causes of product defects or adjust the sensitivity of the error detection system. To do this, they need a precise overview of the next steps at all times without being burdened by unnecessary information. Setup personnel, on the other hand, need access to a comprehensive set of expert settings that, despite their complexity, must be clearly structured, transparent, and safe to use.

Design and Technology in Interaction

The solution developed combines technical performance with a clearly structured, easy-to-understand operating concept. Modular overview graphics can be flexibly adapted to different setups and support users in all work steps. Graphical aids are available for the spatially demanding control of plate rotation, which clearly illustrate complex processes and facilitate precise settings. Context-based navigation complements the classic parameter lists and ensures that relevant information is visible at the right moment. Switchable themes and variable display sizes also allow adaptation to different environments, lighting conditions, and task profiles.